Custom CNC Machining Services are a perfect way to get your company’s products created at a quality that is higher than the average. These services allow your company to create parts for their product with precision and accuracy, in addition to saving time and money.

Table of Contents

Why is Custom Machining so important?

Custom machining is an essential part of manufacturing, because it allows for precision and accuracy in the production process. Custom machining services can be used to create parts that are specific to a customer’s needs, or to produce components that are unique or difficult to manufacture using standard methods.

A custom machined component can be more accurate and durable than a component manufactured using standard methods. Custom machining also allows for the production of components that are difficult or impossible to make using other techniques. For example, custom machining can be used to create components out of exotic materials such as titanium or carbon fiber.

Furthermore, custom machining can speed up the production process by allowing for the production of components that are customized specifically to a customer’s specifications. Custom machining services can also be used to produce parts that are difficult or impossible to produc eusing standard methods.

What are the benefits of custom machining?

Custom machining services can provide significant benefits for manufacturers. Some of the most important benefits include:

– Increased production efficiency. With custom machining, manufacturers can save time and effort by performing specific tasks that are either difficult or impossible to do by hand.

– Increased accuracy and precision. Custom machining can help ensure that products are accurately designed and manufactured, resulting in greater quality and reliability.

– Reduced costs. By using custom machining services, manufacturers can reduce the cost of parts and assemblies by eliminating the need to make multiple copies or versions of components.

– Increased creativity and innovation. When designers have access to precise manufacturing tools, they can create innovative products that wouldn’t be possible with traditional methods.

Types of CNC Machines

There are a variety of types of CNC machines, all with different capabilities and applications. In this article, we will cover the most common types of CNC machines and their uses.

- Computer Numeric Controlled Machine (CNC)

The first type of CNC machine is the computer numeric controlled machine (CNC). This type of machine uses computers to control the movement of the cutting tools, which allows for very precise cuts. CNC machines are used for a variety of purposes, including manufacturing parts and products.

- Laser Cutter/Engraver

The second type of CNC machine is the laser cutter/engraver. This type of machine combines the precision and accuracy of a CNC machine with the ability to create patterns or images using lasers. Laser cutters can be used to make intricate designs or logos, while engravers can be used to create text or images onto metal or other materials.

- Water Jet Cutter

The third type of CNC machine is the water jet cutter. This type of machine uses high-pressure water jets to cut materials quickly and easily. Water jet cutters are popular due to their versatility – they can be used for a variety of different tasks, including fabricating parts and products.

How does a CNC machine work?

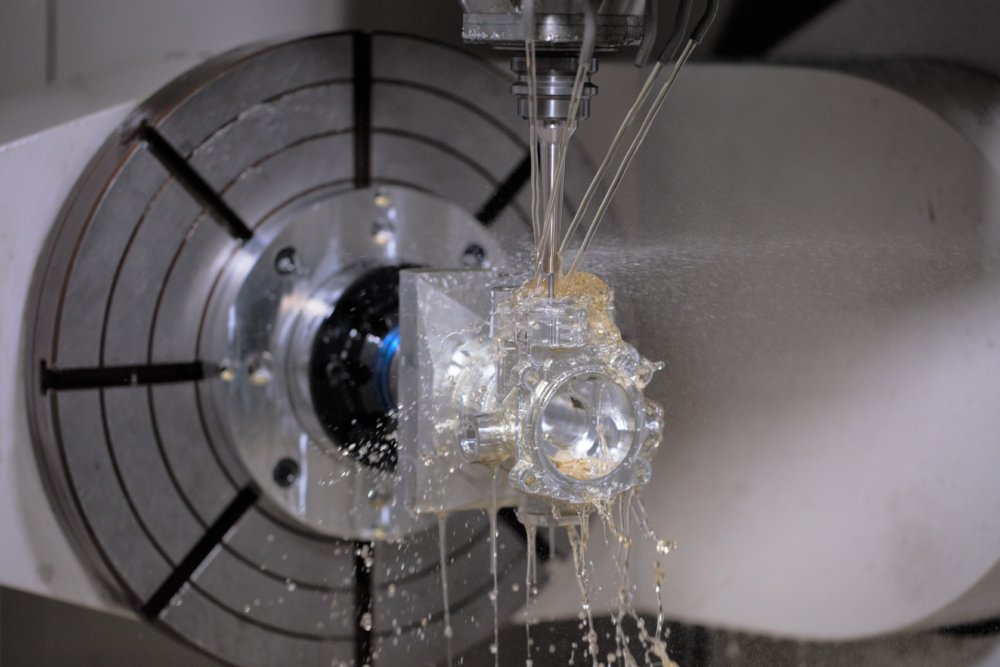

A CNC machine is a computer-controlled machine used in manufacturing to cut parts from a solid piece of material. The machine uses a cutting tool to create precise and repeatable cuts, which can then be assembled into a finished product.

The basic principles behind how a CNC machine works are simple. A computer is programmed with the details of the desired cut, and the machine’s position and movement are controlled by gears, motors, or other automated mechanisms. The cutting tool, typically an X- or Y-axis milling cutter, is moved along the workpiece according to the instructions given by the computer. Whenever the tool makes contact with the workpiece, it causes a tiny bit of metal to be shaved off. This process is repeated thousands of times per second, and as a result, detailed parts can be manufactured with precision and speed that would otherwise be impossible using traditional methods.

Custom cnc machining service are often used in manufacturing processes where accuracy and precision are critical. Examples include aircraft parts such as wings and fuselage sections, medical devices such as CAT scanners and MRI machines, automobile components such as steering wheels and brake rotors, and many other types of products. Because CNC machines can produce extremely high levels of accuracy (down to billionths of an inch), they are often chosen over more traditional manufacturing techniques when quality is essential. In some cases, CNC machines may even replace traditional manufacturing methods altogether – making them ideal for high-volume production situations where speed and efficiency

The Process of Designing for Manufacturing

In order to design for manufacturing, it is important to have a clear understanding of the process. The steps in the process are:

1) Define the requirements

2) Select a CAD software

3) Create a preliminary design

4) Modify the design based on feedback from manufacturing

5) create a final design

6) Print and test samples

7) Make modifications and re-test samples

8) Finalize production drawings and specifications

9) Order parts and materials

Cost to Customize a Product

Manufacturing is an industry that requires a lot of customization. Customizing a product can be expensive, but it can also be a very rewarding experience. There are many different ways to customize a product, and each method has its own costs and benefits.

One way to customize a product is to have the manufacturer make changes to the design. This is usually the most expensive way to customize a product, because the manufacturer needs to develop a new design from scratch. The cost of developing the new design will depend on the complexity of the requested changes, but it can often be quite expensive.

Another way to customize a product is to have the manufacturer make modifications to an existing design. This approach is cheaper than developing a new design, but it does not always result in better products. It depends on how well the modifications match the original design and how much work needs to be done to make the modifications.

In some cases, it may be possible for customers to customize products themselves. This approach is cheaper than having the manufacturer modify an existing design, but it can still be expensive if there are large changes needed made. It also depends on how skilled customers are at customizing products and what tools they need access to in order to do so.

All things considered, customizing a product can be costly and time-consuming, but it can also be very rewarding when done correctly.

Conclusion

If you’re looking for a custom machining service that can help you with your manufacturing needs, look no further than our team at CNC Machining Services. We offer a wide range of services that can help you with everything from turning parts to creating complex assemblies. Whether you need a one-time project or ongoing support, we have the tools and expertise to get the job done right. Contact us today to learn more!