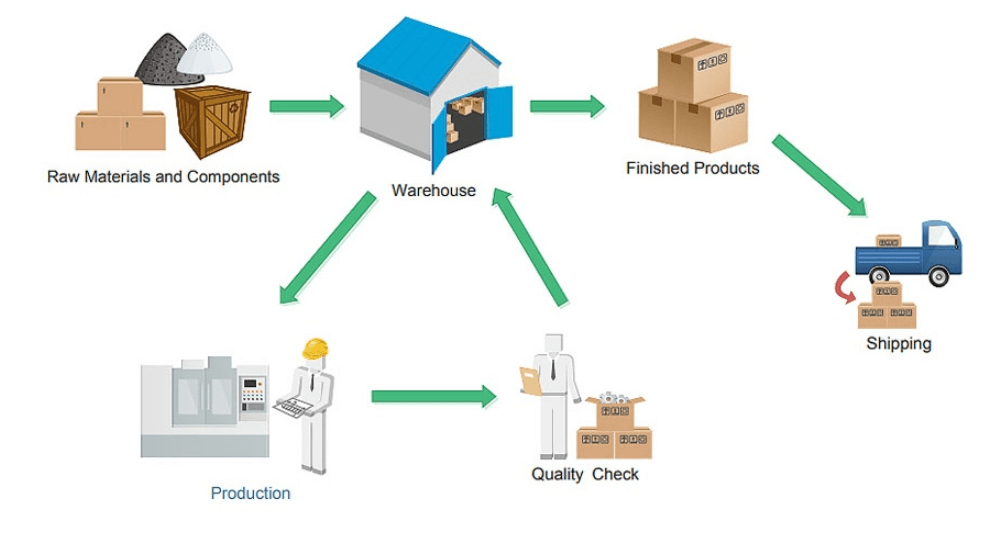

Discover how to revolutionize your inventory management with our simple, four-step guide. This post will walk you through the process of implementing an effective inventory management system, helping you increase efficiency, reduce costs, and improve overall business operations.

Table of Contents

Analyzing Current Inventory Management Practices

As you set forth to enhance your inventory management, remember, the groundwork has already been laid. The practices currently in use are treasure troves of insights, pinpointing strengths to leverage and weaknesses to rectify. Start by scrutinizing existing systems. Look beyond the surface, beyond what simply “works”. Are there areas where efficiency is being bottlenecked or where errors are creeping in? Identifying these rough spots will act as a roadmap for improvement.

Next, assess the operational efficiency. An overflowing warehouse might appear prosperous, but it may also hint at overstocking or inadequate sales forecasting. A clear understanding of how well your current inventory management system is functioning will reveal optimization opportunities. And remember, we’re in the age of data. It’s not just about stock count—it’s about turnover rates, order accuracy, and carrying costs. Listen to what these figures are telling you. It’s through the lens of data that the path to superior inventory management comes into sharp focus. Also, it is necessary to know about warehouse management system for consideration.

Determining Your Inventory Management Needs

Embarking on the journey of identifying your inventory management needs is like exploring uncharted territories, with your business requirements being the compass guiding you. This isn’t a realm where a “one-size-fits-all” approach holds water; here, customization is the potent tool. Factors such as your industry, size of the business, and the nature of products or services you offer will distinctly shape your needs. Your ideal system isn’t an elusive creature, rather it’s one that aligns with your current needs and growth projections. Therefore, features like scalability, user-friendliness, and future-readiness should be high on your checklist.

The symphony of inventory management is orchestrated by elements like real-time tracking capabilities and reporting features. Imagine having the power to peer into your inventory status whenever you wish and using that information to make data-driven decisions. That’s the magic real-time tracking brings to the table. Similarly, robust reporting features act as your faithful scribes, presenting data-rich narratives to help streamline decision-making. Additionally, integration capability with your existing setup is vital. The aim is to create a seamless, well-oiled workflow. Therefore, identifying your inventory management needs isn’t merely a task of ticking boxes; it’s about finding a solution that fits your business as snugly as a tailored suit, striking a balance between function and usability.

Selecting the Right Inventory Management Software

Choosing the right inventory management software can feel like being in a digital orchard full of varied, vibrant options. To select the right one, approach it like an investigative expedition. Start by assembling a list of potential contenders, paying close attention to user reviews – they’re like trusted whispers in a crowded marketplace. While cost is a factor, your focus should be on the value you gain in return.

Once you’ve narrowed down your options, immerse yourself in software demonstrations and trials. This phase is akin to test-driving a car; it’s not just about the exterior aesthetics, but how it feels in operation. Compatibility with existing systems, functionality, and user experience are crucial elements to consider. Remember, selecting software is more than just about ticking off features; it’s about having reliable after-sales support too. Thus, evaluate the software provider’s customer service for its availability and responsiveness.

The importance of warehouse management consulting to an inventory management system is as a compass in the vast labyrinth of inventory processes. It goes beyond merely organizing and storing items, aiming to instigate efficient systems, streamline operations, and minimize bottlenecks. It aids in choosing and deploying apt inventory management systems, ensuring an accurate, real-time overview of stock levels, better forecasting accuracy, cost savings, and improved customer satisfaction. In essence, warehouse management consulting is the catalyst propelling your inventory management system from mere competence to remarkable efficiency.

Implementation and Training

Venturing into implementation may feel like navigating a dense forest with only our new software as a compass and our objectives as guiding stars. However, with the right groundwork, we can chart a clear path. Understand that this process won’t be instantaneous—much like Rome wasn’t built in a day. It commences with data migration, which is much like moving homes; shifting your current inventory data into the new software. This detailed, labor-intensive step sets the foundation for your new inventory management system.

The heart of this journey is staff training. The new system’s success hinges on your team—much like a symphony relies on an orchestra. Conduct training sessions to equip your team with the knowledge and confidence they need to operate the new system. Fostering an environment of curiosity and learning is critical. With your team comfortable and the new system in place, remember to consistently monitor for any hiccups. These aren’t roadblocks but chances to refine our path. Thus, we embark on a journey toward a more efficient inventory management system. Fasten your seatbelts—it’s set to be an enlightening ride.

Conclusion: Monitoring Success and Making Adjustments

Just as the universe is in constant motion, so is the sphere of inventory management. Post-implementation, it’s vital to remember that this is not the end, but rather a new beginning on our journey. Success lies in tuning into the rhythm of regular reviews, deciphering the tales told by data and feedback, and dancing with the tempo of technological and market changes. So, as we anchor our ship at the end of this exploration, remember to keep your sails ready for the ever-changing winds of inventory management. This adaptability, this readiness to embark on new courses, is what propels us towards the horizon of efficiency and productivity. And with that, we wrap up our voyage, only to unfurl the sails for the next one.