Introduction:

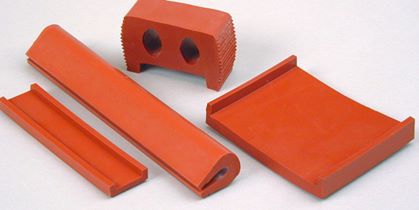

Silicone rubber molding is a highly versatile and reliable process used worldwide by manufacturing and engineering industries. It is often used to create complex shapes and intricate designs that would be difficult or impossible to make using traditional molding methods. With its wide range of applications, silicone rubber molding has become an essential tool for businesses in many different industries. Silicone rubber molding offers precision and accuracy impossible with other molding techniques, from aerospace components to medical devices.

Strength and Durability

The strength and durability of silicone rubber molds make them an attractive option for many industrial applications, such as automotive manufacturing, consumer goods production, medical device fabrication, sporting goods production, electronics assembly, and more.

Their composition makes silicone rubber molds possess superior strength and durability compared to other materials. These properties ensure that silicone rubber mold can withstand high pressures and temperatures while remaining flexible. This makes them ideal for casting or pressing applications involving high temperature and pressure. Additionally, these types of molds are resistant to abrasion, which helps maintain the integrity of the product being produced.

Temperature Tolerance

Due to their temperature tolerance and flexibility, silicone rubber molds are a popular choice for many industrial makers. Silicone rubber molds can withstand temperatures up to 500°F (260˚C) and can be used in applications requiring extreme heat resistance. They provide excellent detail for intricate designs, making them suitable for producing complex parts with fine details and tight tolerances. In addition, silicone rubber molds are highly durable and have high tear strength, making them ideal for use in demanding production environments.

Cost Savings

Silicone rubber molding is a cost-effective solution for businesses looking to save money on their projects. The process uses heat and pressure to produce high-quality rubber molds that can be used in many industries. It’s a simple, efficient way to create custom shapes and sizes without needing expensive materials or machinery. The molds are also durable enough to last through multiple production runs, saving money over time.

The cost savings of silicone rubber molding don’t stop there, either. Not only does it require minimal setup costs and no specialized equipment, but it also offers an economical alternative to other processes, such as injection molding. Additionally, because of its flexibility, silicone rubber can easily conform to any shape or size necessary for the project. This makes it ideal for creating intricate designs with a low-price tag.

As the demand for silicone products in various industries continues to increase, many businesses are turning to reputable silicone manufacturers for their sourcing needs. Silicone manufacturing is a complex process that requires specialized expertise and specific machinery and materials. By working with an experienced silicone manufacturer, companies can be assured of high-quality parts that meet even the most stringent specifications.

Conclusion:

In conclusion, silicone rubber molds are an excellent option for accurately creating complex objects. They are easy to use, cost-effective, and save time when it comes to the production of products. Not only that, but they provide a safe working environment as they are non-toxic, non-corrosive, and can be used for multiple applications. Silicone rubber molds should be at the thrombus of the list for those looking for a reliable and strong mold material.