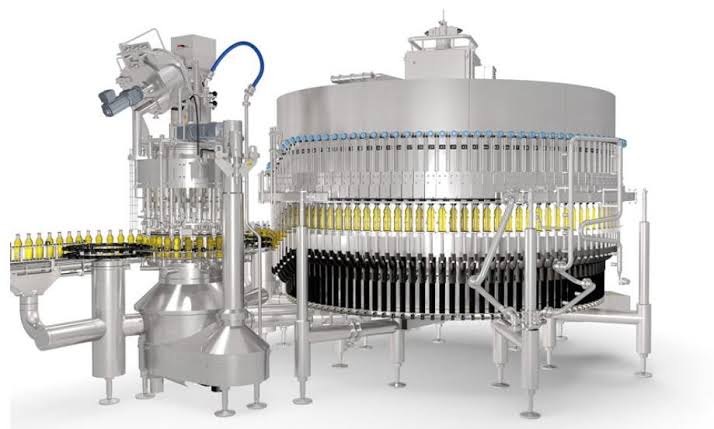

The preferred liquid filling machine in a factory is certain to depend on a variety of factors. It not only has to match the type of liquid and bottle but should also complement the current budget and future growth. Here are a few things to help identify the right liquid filling machine:

Table of Contents

Type of liquids

A major consideration with the filling machine relates. To the type of products that are being bottled. Liquids can be sticky, thick, and semi-fluid in consistency, so it is essential to use a machine that matches. For instance, the thick liquid is best paired with the piston filler. And the thin liquid goes well with the gravity filler. Some liquids can be satisfactory using the same machine, but it is generally beneficial to always stick to the specific type of machinery to complement the product.

There are quite several different CSD filling line in the market today. Among the major types are the piston filler, rotary liquid filler, and straight-line liquid filler. These machines come in fully automatic, semi-automatic, and manual versions too. If you are getting into the food and beverage packing industry, or if you are going to become a floor manager in the industry, knowing the difference between these machines is essential.

Different Types of Machines

There are several different types of machines used in the world of beverage bottling and filling. For example, there are machines for liquid filling, bottle capping, bottle plugging, bottle labeling, born-on dating, and handling. Each of these machines can provide years of high-quality performance and fit almost any application, but floor managers need to make the right selection.

To start, floor managers need to be considerate of the type of liquids their production line is responsible for filling. Are the liquids viscous or non-viscous? There are liquid filling machines that can handle foaming products, too. Many machinery manufacturers promise a high degree of accuracy with their filling equipment, but identifying which type of liquid a company needs to bottle can make finding the right filling machine much easier.

How to identify best filling machine

A second issue to identify an answer for before choosing filling machinery for your bottling warehouse is the environment. Depending on the product your warehouse bottles, there are different grades of sanitation floor managers need to consider. Food and pharmaceutical bottling equipment sanitation codes, while stringent, are probably less demanding than those in hazardous or corrosive situations.

First and foremost, beginning CSD filling line levels will play a large part in choosing the correct level of automation for a filling machine. If a company is only looking to supply a local or regional area, tabletop or uniframe packaging systems may be the ideal solution. Tabletop filling machines allow operators to create a filling station on just about any tabletop surface.

These machines will usually include a slide track and the operator will move bottles under the fill nozzles – which can range anywhere from one to four nozzles. Once under the nozzles, a footswitch, finger switch, or another similar form of activation lets the operator start the filling cycle. Once bottles are filled, they are manually moved from under the fill heads and replaced by empty bottles to start the process again. Tabletop machines are simple to use and are a cost-effective tool for short-run products or low production needs.

In the liquid bottling and filling industry, there are a lot of categories of different machines all with specific purposes. There are machines for bottle labeling, bottle plugging, bottle capping, liquid filling, and many more. With proper handling and maintenance, these machines can last for years and years. However, before the operation of the machine, the business owner or floor manager must first select the right machine for the business.

The first thing that should be considered is the type of liquid that is going to be handled by the machine. For example, some machines can handle foaming liquids and some cannot. Any packaging equipment manufacturer will promise good precision in their machines. However, determining the liquid to be handled by the machine can lead. To better decisions to avoid unwanted problems in the future.

Thing to consider when choosing filling link

Another thing to consider when choosing a csd filling line is the working environment it is going to be situated. There are strict sanitation and cleanliness codes when it comes to bottling liquids. If you think pharmaceuticals and food sanitation and cleanliness codes are strict, wait until you get to know the sanitation and cleanliness codes of corrosive and hazardous liquids. All these codes go the same for the filling machine as with the environment.

There is a filling machine system out there that can be designed to fit. Just about any need in liquid packaging. From liquid filling for bags, pouches, and jars to large-scale, high viscosity filling in heavy containers, there is a machine out there for your needs. Answering a few critical questions before you start shopping and pricing machinery will make you much better informed when it comes to making a purchasing decision.

Also, do not forget about size. Size is another determining factor in the quest for the best filling machine for your business. Naturally, the bigger the container of the machines, the more liquid it can hold and bottle. Likewise, if you are filling barrels and drums, you will need bigger equipment as compared to when you are filling medicine bottles and jars. The size of the container is also very important to determine before choosing a filling machine. If your filling needs are for beverages or drums, then the machine you need will be vastly different than if you need to fill cups or vials.

Final Words

All in all, there is just about any kind of machine that can handle any type of filling situation. These range from viscous liquids filling containers, to non-viscous liquids filling jars, pouches, bags, foil pouches, plastic cups and bottles, and glassware. However, not to worry, your chosen packaging equipment manufacturer will be glad to help you out in choosing. It would be better, though, to brush up on filling machine knowledge for an easier and smoother transaction.