In today’s fast-paced and interconnected world, the need for seamless data transmission in rotating systems has become increasingly crucial across various industries. To overcome the challenges of transmitting data across rotating interfaces, engineers have developed innovative solutions such as Ethernet slip rings and PCB slip rings. These remarkable devices play a significant role in ensuring uninterrupted data connectivity in rotating applications. In this article, we will explore the functionalities, applications, and benefits of Ethernet slip rings and PCB slip rings, shedding light on their significance in modern industries.

Understanding Ethernet Slip Ring

Ethernet slip rings, also known as rotary data connectors, are specialized devices designed to maintain continuous data connectivity between stationary and rotating components. They facilitate the transfer of high-speed Ethernet signals, power, and other communication protocols across rotating interfaces. Ethernet slip rings are particularly valuable in applications that require real-time data transmission, control signals, or high-bandwidth communication.

Features and Components of Ethernet Slip Rings

Ethernet slip rings incorporate several key components that work together to ensure seamless data transmission. These components include:

Slip Rings: The core element of an Ethernet slip ring, slip rings enable the transfer of electrical signals and power across the rotating interface. Typically made of precious metal alloys like gold or silver, slip rings ensure low electrical resistance and reliable performance.

Brushes: Carbon or graphite brushes establish electrical contact between the stationary and rotating components, enabling the transfer of signals and power through the slip ring.

Housings: Ethernet slip rings are securely housed within robust enclosures, protecting them from environmental factors such as dust, moisture, and vibrations. The housing also helps maintain the alignment and integrity of the slip ring assembly.

Connectors: Equipped with connectors, Ethernet slip rings ensure a secure and reliable connection between the stationary and rotating components, facilitating easy integration.

Applications of Ethernet Slip Rings

Ethernet slip rings find applications in various industries where seamless data and power transmission across rotating interfaces are essential. Some common applications include:

Wind Turbines: Ethernet slip rings enable real-time data communication between the stationary base and the rotating blades in wind turbine systems. This facilitates remote monitoring, control, and optimization, leading to improved performance and maintenance efficiency.

Robotics and Automation: Ethernet slip rings are utilized in robotic systems to transmit control signals, sensor data, and video feeds from stationary controllers to rotating joints. They enable precise control and seamless operation of robotic systems.

Medical Imaging: In medical imaging equipment such as CT scanners and MRI machines, Ethernet slip rings ensure uninterrupted data transfer between the stationary console and the rotating gantry. This allows for the transmission of high-resolution images and patient data.

Industrial Automation: Ethernet slip rings facilitate real-time data exchange between stationary controllers and rotating machinery in industrial automation applications. They enable efficient monitoring, control, and synchronization of industrial processes in industries such as packaging, material handling, and assembly lines.

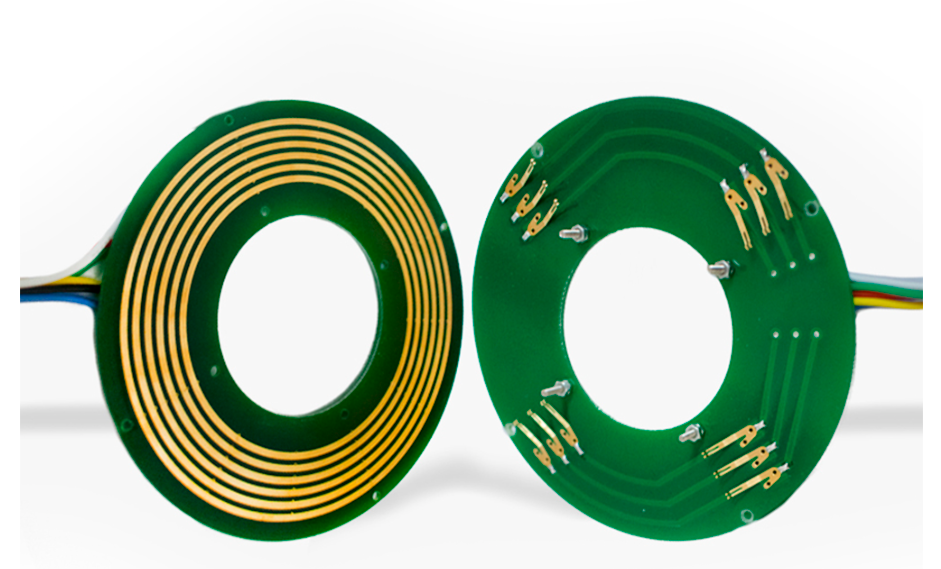

Understanding PCB Slip Ring

PCB slip rings, also known as printed circuit board slip rings, are compact and versatile devices designed to transmit electrical signals, power, and communication protocols across rotating interfaces. They are constructed using printed circuit boards, which are integrated with conductive traces and components for data transmission.

Features and Components of PCB Slip Rings

PCB slip rings possess unique features and components that make them suitable for specific applications. These include:

Compact Design: PCB slip rings have a compact design, allowing for easy integration into space-constrained systems. They are particularly suitable for applications where size and weight are critical considerations.

Printed Circuit Boards: PCB slip rings utilize printed circuit boards to establish electrical connections and transmit signals. These boards are carefully designed and manufactured to ensure reliable performance and signal integrity.

Conductive Traces: PCB slip rings feature conductive traces on the printed circuit boards, which facilitate the transmission of electrical signals and power across the rotating interface.

Components Integration: PCB slip rings can integrate various components such as resistors, capacitors, and amplifiers on the printed circuit boards, enabling additional functionalities and signal conditioning.

Applications of PCB Slip Ring

PCB slip rings find applications in numerous industries where compactness, customization, and high performance are crucial. Some notable applications include:

Robotics and Automation: PCB slip rings are extensively used in robotics and automation systems to transmit control signals, power, and sensor data across rotating joints. They enable precise control and seamless operation of robotic arms and other moving components.

Surveillance and Security Systems: PCB slip rings play a vital role in surveillance and security systems, allowing the transmission of video signals, power, and control data between stationary and rotating components. They are widely used in applications such as rotating cameras and pan-tilt-zoom systems.

Medical Devices: In medical devices that require rotating components such as X-ray machines and medical imaging equipment, PCB slip rings ensure uninterrupted data transmission between stationary consoles and rotating parts. They enable the transmission of signals and power required for diagnostic imaging and medical procedures.

Test and Measurement Equipment: PCB slip rings are commonly employed in test and measurement equipment, enabling the transmission of signals, power, and data between stationary devices and rotating test probes or sensors. This allows for accurate data collection and analysis.

Conclusion

Ethernet slip rings and PCB slip rings have revolutionized data transmission across rotating interfaces, addressing the challenges faced by various industries. These advanced devices provide reliable and high-speed data transmission while maintaining the integrity of electrical signals, power, and communication protocols. Whether in wind turbines, robotics, medical imaging, or industrial automation, Ethernet slip rings and PCB slip rings have become indispensable components in modern rotating systems. As technology continues to advance, these devices will further evolve to meet the growing demands of industries, ensuring efficient and uninterrupted data transfer in the face of rotational challenges.