PCBA one-stop service is the current trend in the PCB industry. It will bring convenience and efficiency to customers, and help companies save time and cost.

PCBA one-stop service refers to the complete set of PCBASIC production services provided by a single supplier. The main advantage of PCBA one-stop service is that it can greatly reduce the cost of product development, shorten the development cycle, improve quality control and enhance efficiency in production.

PCB is a product that has been widely used in the electronics industry. It is often said that PCB is the “backbone” of all electronic products. Its advantages are:

Table of Contents

The advantages of PCBA one-stop service:

1. The cost advantage:

The general assembly process is divided into many stages, and each stage requires a large number of workers and equipment, which leads to high labor costs and equipment depreciation costs. In contrast, PCBA one-stop service can be conducted by using automated equipment in a point-to-point manner, so labor costs are reduced by more than 50%. The same applies to equipment depreciation costs.

Our main goal is to provide our clients with an exceptional level of customer service. Our team has been working together for many years, which enables us to provide our customers with excellent communication and problem-solving skills.

.As a result, we use state-of-the-art equipment, professional software, and advanced testing methods to ensure that each project receives the attention it deserves.

Our team members are experienced engineers and technicians who have been working in the CAD industry for more than 10 years. We have plenty of experience in producing different kinds of boards such as high-density FR4 boards, rigid-flex boards, and flexible flex boards.

2. The quality advantage:

Due to the manual operation after each assembly process, there are many chances for human error during assembly work; in addition, some small components may be damaged during manual operation due to poor handling skills or improper installation and other factors. In contrast, an automated assembly can effectively reduce these errors caused by human factors or damage caused by poor handling skills; moreover, it can also improve product quality and reduce customer complaints about product defects

Finally, there is a third advantage:

3. It Reduces Risks.

If you have a prototype made by an external company and then have several iterations of changes made based on customer feedback before releasing it on the market, then there is no guarantee that this process will result in a successful product launch. On the other hand, if you use a PCBA one-stop service provider for all aspects of your product development process (including marketing), then all decisions about how your final product should look and what features it needs are made by professionals who know exactly what works best for their customers

Our main goal is to provide our clients with an exceptional level of customer service. Our team has been working together for many years, which enables us to provide our customers with excellent communication and problem-solving skills.

.As a result, we use state-of-the-art equipment, professional software, and advanced testing methods to ensure that each project receives the attention it deserves.

Our team members are experienced engineers and technicians who have been working in the CAD industry for more than 10 years. We have plenty of experience in producing different kinds of boards such as high-density FR4 boards, rigid-flex boards, and flexible flex boards.

UETPCB is an integrated PCB Prototype And Production Services

UETPCB is a PCB manufacturer based in Shenzhen, China. It provides a one-stop service for PCB manufacturing, prototyping, and PCB assembly. As a China PCB manufacturer, UET PCBA was founded in 2005, based in Shenzhen, China.

UETPCB is a technology company that specializes in the design and manufacture of PCBs and other electronic products. We offer our customers high-quality products at competitive prices with a fast turnaround time.

Our main goal is to provide our clients with an exceptional level of customer service. Our team has been working together for many years, which enables us to provide our customers with excellent communication and problem-solving skills.

.As a result, we use state-of-the-art equipment, professional software, and advanced testing methods to ensure that each project receives the attention it deserves. Our team has been working together for many years, which enables us to provide our customers with excellent communication and problem-solving skills.

Our team members are experienced engineers and technicians who have been working in the CAD industry for more than 10 years. We have plenty of experience in producing different kinds of boards such as high-density FR4 boards, rigid-flex boards, and flexible flex boards.

Printed Circuit Board Assembly (PCBA)

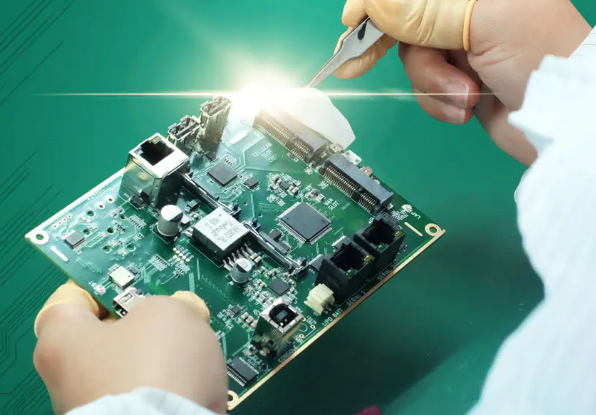

Printed Circuit Board Assembly (PCBA) is a manufacturing process that joins electronic components to a printed circuit board (PCB). A typical PCBA involves placing the components onto the board, soldering them into place, and then testing to ensure that they are working properly.

The process begins with testing each individual component to ensure they are functional and do not have any defects. The components are then soldered onto a PCB in a controlled manner. Once all components have been soldered, the board is inspected again for defects. If no defects are found, the board goes through additional testing before being sent out to customers as part of the final product assembly

Printed circuit board assembly (PCBA) is the process of assembling a printed circuit board (PCB) by attaching electronic components to the PCB. The term can also refer to the equipment used to assemble PCBs.

The process of assembling a PCB can be broken down into three main stages:

- Surface preparation: This involves cleaning the surface of the PCB and removing any oils and contaminants from it. This is done using various chemicals such as alcohol or acetone or an ultrasonic cleaner.

- Soldering: The next stage involves soldering the components onto the PCB. This is done manually by hand or with a reflow oven.

3. Testing: Once all components have been soldered onto the board, it must be tested to ensure that all connections are working correctly before being shipped off for use in products like mobile phones or computers

electronicstalk

August 20, 2022“Electronicstalk.com” is a website that provides news and information related to the electronics industry. It covers topics such as electronic components, semiconductor technology, product launches, industry trends, and more. The website served as a resource for professionals, engineers, and enthusiasts interested in staying updated on developments in the electronics field.

Electronicstalk.com is a valuable online resource for anyone interested in the world of electronics. This website offers a wide range of articles, news, and information related to electronics and technology.

One of the strengths of electronicstalk.com is its up-to-date content. The site consistently provides the latest news and insights into the electronics industry, making it an excellent source for staying informed about emerging trends and developments.