Modern electrical gadgets must have printed circuit boards (PCBs). They enable electrical communication between different electronic components and act as a platform for their connection. Impedance control PCB demand has greatly grown recently, particularly in high-speed applications. In this post, we’ll give you a thorough introduction to impedance control Boards, outlining their description, operation, uses, and advantages.

Table of Contents

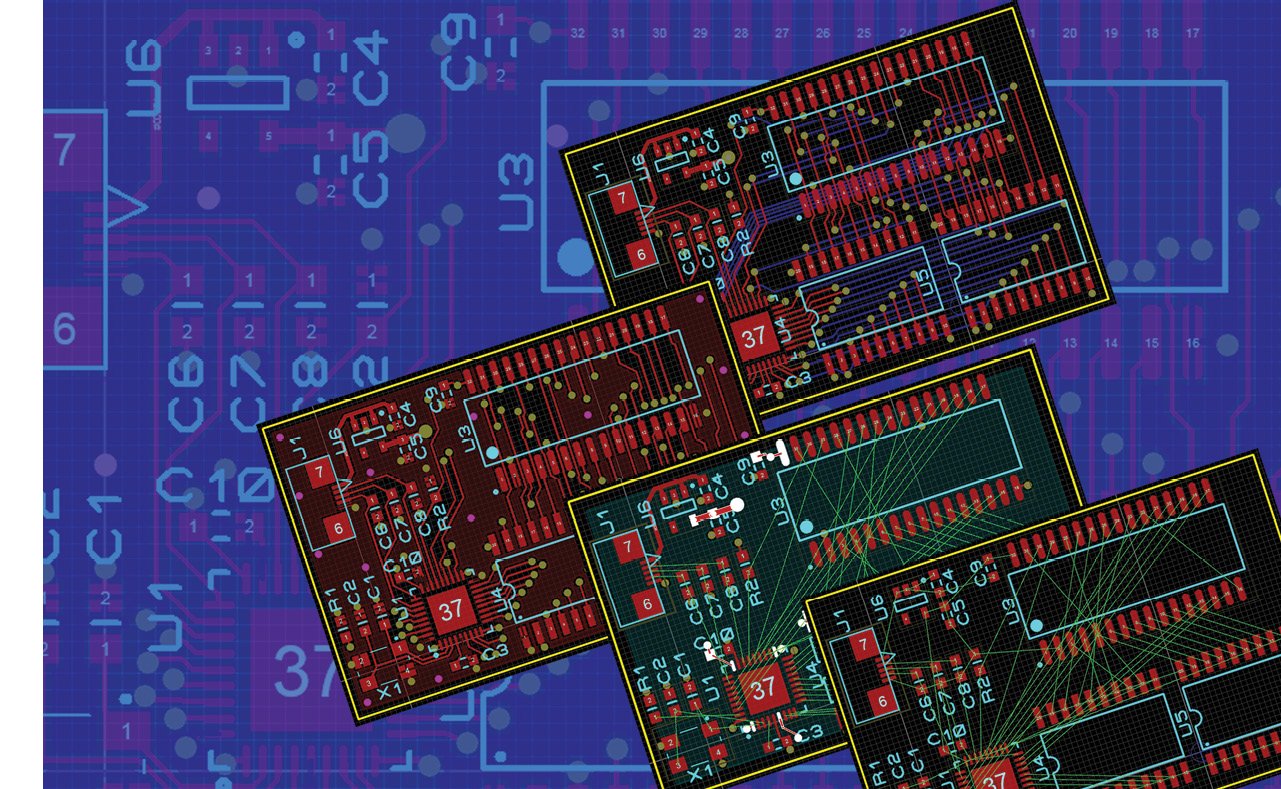

What is an Impedance Control PCB?

Impedance Control PCB ensures certain impedance value for signals travelling through a PCB must be maintained. A PCB’s impedance is defined as its resistance to the transmission of electrical impulses. It is expressed in ohms and depends on the physical properties of the PCB, including its thickness, dielectric constant, and trace width.

In high-speed applications where signal integrity is important, impedance control Boards are employed. These PCBs are made to reduce signal reflection, noise, and distortion, which can degrade signals and have an impact on the device’s overall performance.

Working Principle of Impedance Control PCB

Controlled impedance is the underlying theory behind how PCBs operate. The electrical qualities of the signals travelling through a PCB and its physical attributes together determine its impedance. The physical properties of the PCB, such as trace width, spacing, and dielectric constant, must be meticulously managed during the manufacturing process in order to preserve a specified impedance value.

Specialized methods, such as controlled copper thickness, trace width, and dielectric constant, are used to create impedance control Boards. With the aid of these methods, the PCB may keep its desired impedance value even when the electrical environment in which the signals travelling through it changes.

Also read: Razer Blade 15 2018 H2 Buying Guide. Still Top Laptop for Gamers?

Applications of Impedance Control PCBs

Impedance control PCBs are frequently employed in numerous high-speed applications, such as:

Telecommunications

Impedance regulation PCBs are frequently found in networking devices including switches, routers, and other telecommunications equipment. High-speed data transfer with little distortion or signal loss is necessary for these devices.

Medical Devices

For precise and rapid diagnosis, medical equipment need high-speed data transfer. Medical gadgets include imaging equipment, patient monitoring systems, and surgical instruments all make use of impedance control PCBs.

Aerospace

High-performance electronic devices that can survive abrasive environmental conditions are required for the aircraft sector. Avionics, navigation systems, and other aircraft applications require impedance control PCBs.

Automotive

The automotive sector demands electrical equipment that can function in high-vibration and temperature environments. Engine management systems, infotainment systems, and other vehicle applications all require impedance control PCBs.

Benefits of Impedance Control PCBs

An Increase In Signal Integrity

Impedance control PCBs reduce signal reflections, noise, and distortion, which enhances signal integrity. This guarantees correct signal transmission via the PCB, improving the functionality of the entire device.

Reduced Crosstalk

Crosstalk happens when signals from one trace interfere with signals from another trace. Impedance control PCBs also assist in reducing crosstalk. The performance of the device as a whole may be impacted by this interference and signal deterioration.

Improved Emc Performance

By reducing signal emissions and sensitivity to outside interference, impedance control Boards contribute to better electromagnetic compatibility (EMC) performance. In high-speed applications where EMC performance is crucial, this is extremely significant.

More Flexibility In Design

More design flexibility is provided by impedance control PCBs, which enable engineers to create PCBs with specified impedance values to satisfy the particular needs of their applications. Additionally, this adaptability enables greater control over signal transmission, improving device performance all around.

Conclusion

Since signal integrity is important, high-speed applications need the use of impedance control PCBs. The fact that they are made to retain a particular impedance value enhances signal integrity, lessens crosstalk, and enhances EMC performance. Many different industries, including telecommunications, medical devices, aerospace, and automotive, frequently employ impedance control Boards.

Working with a professional PCB maker with the knowledge and tools to build high-quality PCBs is crucial when developing an impedance control PCB. To guarantee that the PCBs meet the necessary requirements, the manufacturer should be able to offer design support, quality control, and testing services.

In summary, impedance control PCBs are a crucial part of contemporary electronics. They contribute to more accurate and dependable signal transmission in high-speed applications, which enhances the functionality of the device as a whole. Consider employing an impedance control PCB when developing an electronic device that needs high-speed data transmission to guarantee the highest possible signal integrity.