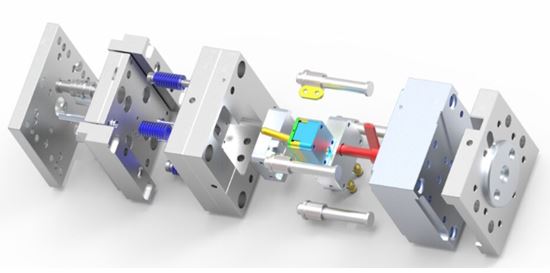

Manufacturing method of injection molding, or injection molding in the United States, produces items by pumping molten material into a mold. Rich experience, well-maintained machinery, professionals in all positions, a customer-focused corporate culture, and a service-conscious workforce are all requirements for a good injection molding supplier. Yes, Prototool is the business for you in this situation.

We have almost ten years of experience in automotive and electronics for consumer injection molding service, therefore we are prepared for any unforeseen circumstance. We think that timely client communication and timely understanding of their demands are the only ways to produce superior products.

The skilled designers at Prototool offer sound guidance to our customers. To assist clients in finding their niche in the market, they are knowledgeable about both the items and the industry.

To speed up the process of developing your product, we can generate thousands of parts. A wide range of materials are available for you to pick from. To get the production going, we maintain an inventory of more than 100 plastic resins. We offer numerous alternatives for finishing molded end products. Plastic molding, insert molding, over molding, and family molding are all aspects of our injection molding capabilities.

Table of Contents

Injection molding of plastic

To create injection molded parts of the highest quality, we use the finest thermoplastic materials. From requirement collection to design review, die and mold production, and finally, to the finished product, we carry out the entire process scientifically.

With ten years of experience and a focus on plastic injection molding, Prototool can assist you in avoiding problems like insufficient capacity, shaky design capabilities, unreliable product quality, and late delivery.

Insert Molding

In insert molding, a pre-made component—typically made of metal—is put into a mold. Preformed molds are over-molded with the necessary thermoplastic resin to produce the finished product. By using our insert molding services, you can obtain items of the highest caliber. The insert is inserted into the mold during the typical production process known as insert molding. Depending on the volume of parts being produced, this insert insertion can either be automated or done manually. The placing is often mechanized for big volumes and manually for smaller volumes.

Over Molding

A thermoplastic material can be over-molded into a second thermoplastic or a liquid silicone rubber material. It enables us to achieve the functionalities and attributes of the product that are necessary. Prototool may occasionally advise you to use our factory’s two-color injection molding technique to complete your specific products, but if your deadlines are flexible and you’re looking to save money, we might advise over-molding instead.

Overmolding is a fairly developed injection molding technique in the market. To make your merchandise more competitive in the market, our qualified personnel will offer you advice based on our nearly ten years of injection molding experience.

Family Mold

When a client requests quick project delivery, we use a family injection mold. It enables us to produce several parts from the same resource in just one production cycle. For this type of injection molding, the mold has several cavities. Each cavity can produce a unique part.

Online Visa Application Form

August 17, 2023It’s in point of fact a nice and useful piece of

info. I am satisfied that you just shared

this useful info with us. Please keep us informed like this.

Thank you for sharing.