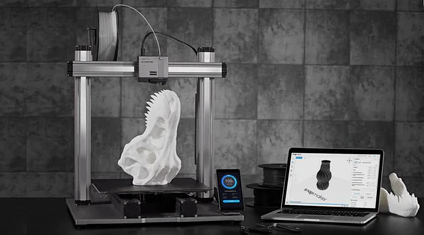

With the help of the Snapmaker 2.0 rotary module, you’ll see that the Snapmaker has some very awesome capabilities that make it the most potent CNC machine. This kind of rotational module is well known for its capacity to print desktop miniatures and other small sculptures in addition to three-dimensional artworks. You may be confident that the craftsmanship you receive will be of the highest caliber once you have the Snapmaker rotary module. Some benefits of using the Snapmaker 2.0 rotary module are listed below.

Advantages of the Snapmaker rotary module

The Snapmaker 2.0 rotary module is compatible with a wide range of materials, including leather, plastic, and wood, to name a few. This provides you the flexibility to select the kind of material you wish to use for your design and the chance to create several prints. With free Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, Snapmaker 2.0’s rotary module can produce 4-axis projects instantly, allowing you to quickly build designs from scratch and produce finished goods.

The fastest sculpture is created when the Snapmaker 2.0 rotary module is utilized, which has a continuous angle rotation of 360 degrees with an angular of 45 degrees per second. This kind of rotary module allows for highly exact control of rotation at 0.2, 1, and 5 degrees on the Touchscreen, allowing you to observe the difference in each action that is performed.

When it comes to printing, there are some items that are quite hollow while also having unevenly curved outer shells. Making the desired curves from such objects is very challenging. The software in a Snapmaker 2.0 rotary module, on the other hand, is quite effective at cutting hollow objects and shells with uneven shapes. The X, Y, Z, and B axes may all move simultaneously and cooperatively thanks to the 4-axis connection support, which gives the rotary module total control.

During the carving process, something could go wrong. You have the option to hit the Snapmaker 2.0 Emergency Stop Button if something goes wrong. Pushing the stop button during an emergency has been developed to add an additional layer of safety when you’re undertaking laser engraving and CNC carving. Once the process has been paused, you can protect your printing from being harmed.

A strain wave gear and a 100:1 reduction gear are necessary for the rotary module to operate at a reduced output speed. This gives room for the three-jaw chuck to have the ability to rotate at a minimum angle of 0.1 degrees, giving you the advantage of working on irregular surfaces and even uneven surfaces without missing a single step.

Purchase of the Snapmaker rotary module is an excellent action you may take, which is essential to your 3D printing profession. This rotary module’s design includes a 4-axis rotary milling cutter and laser engraving, making it suitable for a variety of materials. However, it’s crucial to find out if it has a guarantee before making the final choice in case something goes wrong and needs to be fixed. The provision of post-purchase support is another crucial service that you should receive. Make sure the seller is a respectable one as well.

There you go; those are the benefits you can get by using our rotary module. Snapmaker cares for their client and thuds our products will provide you with extra safety. Apart from safety, you will also enjoy a wonderful working experience. Make up your mind today and visit eu.snapmaker.com. Feel free to contact us in case of any inquiries.