Diesel engine problems can be very overwhelming when you start to have diesel problems, especially if you are unfamiliar with the machine. Wear and tear can cause problems in diesel engine components, but these problems can get more complicated.

This handy guide outlines common diesel engine problems, so you are prepared for the unfortunate problems of using a wide variety of diesel engine components. The diesel engine has a compressor to compress the air.

Both diesel cars use an internal combustion engine, so they are similar to gasoline cars. One difference is that diesel engines have a compression ignition system instead of the spark ignition system used in most gasoline vehicles. In a self-ignition system, diesel fuel is injected into the engine’s combustion chamber and ignites at the high temperatures that occur when the engine’s pistons compress the gas. In contrast to emission control systems for gasoline vehicles, many diesel vehicles have additional after-treatment components that reduce particulates and break down harmful nitrogen oxide (NOx) emissions into harmless nitrogen and water.

Diesel is a common fuel for transportation, and some other fuel options use similar engine components and systems.

Table of Contents

Engine construction

The main components of a diesel engine are similar to those of a gasoline engine and perform the same tasks. Due to the high load, however, the diesel engine components must be significantly more powerful than the components of the gasoline engine.

The walls of diesel engines are much thicker than cylinder blocks, which are generally designed for gasoline engines, and have more braces to provide additional strength and absorb loads. Sturdy blocks are not only stronger, but they can also reduce noise more effectively.

Pistons, connecting rods, crankshafts, and bearing caps have to be stronger than gasoline engines. Depending on the shape of the injector, the combustion chamber, and the swirl chamber, the cylinder head must be designed very differently.

Types of Diesel Engines

The diesel engines have two major types:

1)Two-stroke Engine

A two-stroke engine completes a working cycle in just one revolution of the crankshaft.

2) Four-stroke Engine

This engine completes a working cycle in two revolutions of crankshaft.

Components of Diesel Engine1. Cylinder Block Assembly

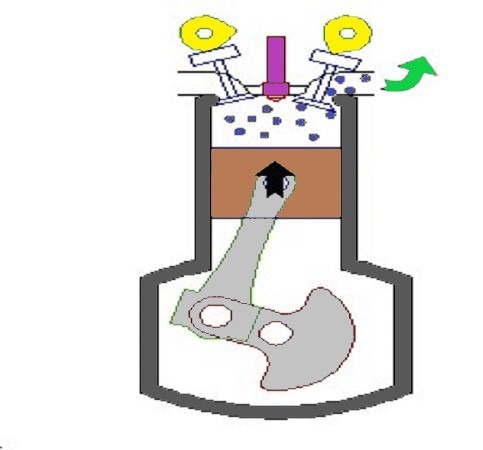

Cylinder blocks are an essential part of 2-stroke and 4-stroke internal combustion engines. This part will be an important part of the various engine compartments that support the machine’s working process. As you can see in the picture above, the shape of the cylinder block is almost the same on each machine, but the details are different. This is because the details of the cylinder block are adjusted by all the components attached to that block.

2. Cylinder Head Assembly

The second component assembly is on top of the engine. Like the cylinder block, this part is also made of cast material. Today’s aluminium head cylinders appear to be an option due to their lightweight and high strength. The device consists of valves and springs, camshafts, rocker arms, and combustion chambers.

3. Piston and connecting rod

The function of the piston is to adjust the internal volume of the cylinder. Why does the cylinder volume have to be adjusted? This allows you to do the working process of a 4-stroke engine. In this case, moving the piston downward increases the volume of the cylinder, and moving the piston upward decreases the volume of the cylinder. The connecting rods are used to move the piston up and down towards the flywheel.

4. Crankshaft

The crankshaft is a cast iron component that converts the vertical movement of the piston into rotary movement. The principle of operation of the crankshaft is the same as when using a bicycle. It is related to the pressure of the piston, so the crankshaft should not be elastic or break under the pressure of the piston. The parts are made of a particularly high-strength and robust ferroalloy.

Reasons of Diesel Engine failure

1) Oil leakages

Oil spills are primarily caused by problems with diesel engine components, such as aging seals and gaskets, and they are not working effectively. If left untreated, oil spills pose a threat to the environment and a severe fire hazard, which can lead to serious diesel problems and even total engine failure.

2) Oil supply problems

Oil supply problems are mainly due to improper use of oil or a lack of oil. Using the wrong type of oil will affect all engine components, and if the engine is not filled, it will run in the air instead of oil, causing engine damage.

3) Using the wrong fuel

Diesel engines are very susceptible to damage from improper refuelling and typically require new diesel engine parts or a completely new engine. To avoid this common problem with diesel engines, carefully check the type of fuel you are using before refuelling.